Our Business

Our Business

Iwaki Takahashi, a company that makes waribashi (disposable chopsticks) out of thinned wood to help revitalize forests, was founded in August 2010.

The Great East Japan Earthquake struck six months later. Our factory was damaged by large aftershocks that continued for around one month after the earthquake, and we were resigned to closing down our business. However, thanks to assistance from people outside the company, we were able to recover by making Kibo no Kakehashi, chopsticks made from thinned cedar wood from the three disaster-struck prefectures.

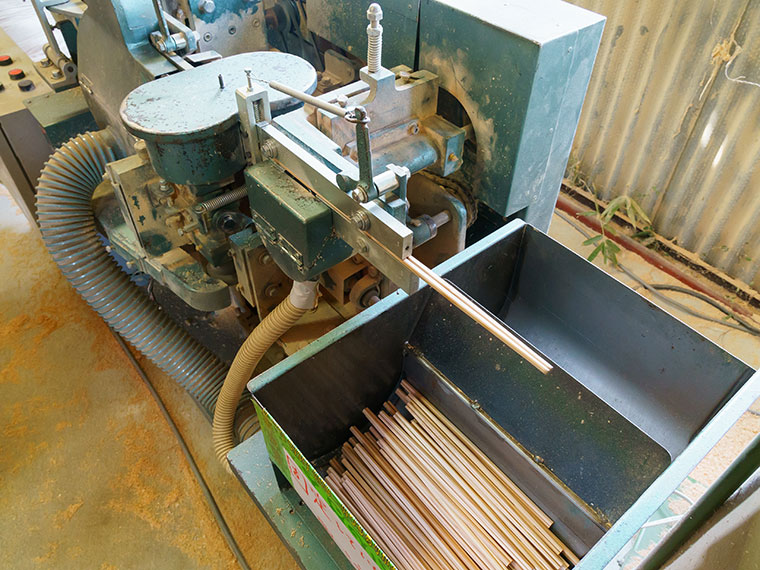

Waribashi manufacturing process

We carry out the entire manufacturing process, from raw material procurement to the finished product. Iwaki Takahashi’s fine-quality products are then carefully delivered to customers.